Polyflex Hoses

Original price was: $198.00.$175.00Current price is: $175.00.

DIAMETERS

1.50IN/38MM

2.50IN/64MM

Manufacturer-provided features and specifications as follows

» STRONG, COMPACT, LIGHT IN WEIGHT AND WILL FI T ON MOST HOSE STORAGE DEVICES

» UNIQUE MERTEX® LINING YIELDS AN EXTREMELY LOW FRICTION LOSS, FOR MAXIMUM FLOW AND SUPERIOR ADHESION FOR LONG LIFE

» PREMIUM ALL SYNTHETIC SINGLE JACKET

» FACTORY MUTUAL AND UL APPROVED AND CAN BE FM AND / OR UL LABELED IN THE SIZES SPECIFIED*

» RESISTANT TO MOST CHEMICALS, PETROL PRODUCTS, OZONE AND U.V. EXPOSURE, HYDROLYSIS, AND ROT AND MILDEW

» REMAINS FL EXIBLE TO -65O F (-55O C)

» MEETS OR EXCEEDS ALL PERFORMANCE REQUIREMENTS OF NFPA 1961, UNDERWRITERS LABORATORIES AND FACTORY MUTUAL

JACKETS

The hose jacket shall be made with high tenacity fi lament

polyester yarn in both the warp and weft directions, to

provide maximum strength to weight ratio and shall have a

minimum filler (weft) yarns of 10 per inch (394 per Meter).

LINING

The lining (waterway) must be made from polyurethane

and must be applied using a fused process that welds the

polyurethane directly to the textile while the hose is being

woven, without the use of adhesives or hot melt. The fused

lining process must create a virtually inseparable unit without

the use of adhesives, yielding an extremely low friction

(pressure) loss by filling in the corrugations of the weave,

creating an ultra thin and smooth waterway. Fire hose made

using adhesives of any type do not meet this specification.

The lining shall be approved for use with potable water.

ADHESION

The adhesion shall be such that the rate of separation of a

1 ½” / 38mm strip of polyurethane, transversely cut, shall

not be greater than 1/4” / 6mm per minute under a weight

of 12 lbs / 5.5 kg.

COLD TEMPERATURE FLEXIBILITY

The hose must remain flexible to -65°F (-55°C).

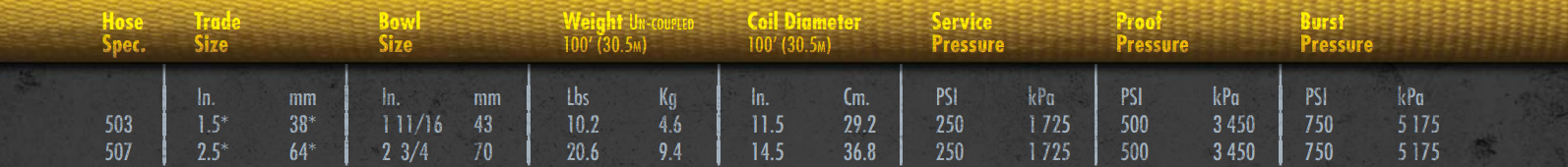

SERVICE, TEST, BURST PRESSURES

Minimum service, test and burst pressures shall be as detailed

in the specification table on the previous page.

KINK TEST

A full length will withstand a hydrostatic pressure of

600 psi / 4140 kPa while kinked.

WEIGHT

Each length of fi re hose shall not weigh more than indicated

in the specification table.

COUPLING SPECIFICATIONS

Couplings shall be in conformance with the current NFPA

standard and made of extruded aluminum, hard coated a

minimum of .002” thick.

They shall be manufactured in North America and permanently

labeled with country of origin. They shall be expansion ring type.

MANUFACTURE

Both hose and couplings must be manufactured in North

America and be NAFTA compliant.

STANDARDS

Must be Factory Mutual and UL approved and can be FM and

/ or UL labeled in the sizes specified*